Troy, IL Residence Pool House EIFS Plastering Contractor

June 20, 2014George Weis Company was chosen as the EIFS plastering contractor to install EIFS (Dryvit) on a pool house and patio addition. With a new stone fireplace and exposed wood beams combined with EIFS the project turned out very well.

We have completed quite a few pool houses completing everything from the ground up or just being the plastering contractor on the project ranging anywhere from Troy, IL to St. Louis, MO.

Casey’s General Store in Troy, IL- EIFS (Stucco) and Drywall Job Begins

February 25, 2014George Weis Company is working together with Kinney Contracting as the drywall contractor to install the drywall and taping of the new Casey’s General Store in Troy, IL, conveniently located right off Interstate 55 on Edwardsville Road. Our scope of the project began at the start of February and is expected to be completed mid-March pending the harsh winter weather.

Additional to the drywall and taping Weis will also be working with TCT Construction as the plastering contractor to perform the EIFS (Exterior Insulation Finish System) of the exterior facade of the new Casey’s General Store in Troy, IL. Weis will be using Senergy to create a unique, cosmetic exterior appeal with its architectural detailing while maintaining an energy efficient building.

Expansion at Zion Lutheran in St. Charles, MO

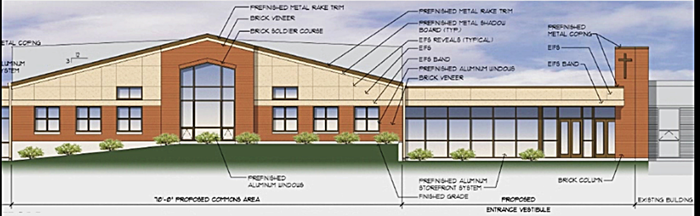

February 20, 2014George Weis Company has been recently paired with Ben Hur Construction as the plastering contractor and drywall contractor to improve and expand upon the existing Zion Lutheran School in St. Charles, MO. The addition will consist of a seven-classroom Early Childhood Center along with the addition of a Commons Area. Weis will be responsible for the exterior and interior steel stud framing, drywall, taping, EIFS (Exterior Insulation Finishing System or Dryvit), and acoustical ceilings. Despite the harsh wintery weather conditions, the determined carpenters of Weis have currently began the construction of the exterior framing and sheathing and Tyvek. The installation of the EIFS will soon follow. Zion Lutheran’s vision of a newly expanded school is expected to reach completion in Summer of 2014.

George Weis Company – Premier Plastering Contractor serving St. Louis, Southern Illinois and the surrounding Metro East area.

Vandalia, IL – EIFS (Stucco) Completed at Huddle House Ember’s Pizza

November 26, 2013Korte Luitjohan Contractors selected George Weis Company to be the Plastering contractor for the brand new Huddle House, to be paired with Embers Pizza, in Vandalia, IL (1 hour 10 minutes from St. Louis, MO). The project began back in July of this year and is expected to open for business within the next couple of weeks. In addition to the installation of the Exterior Insulation and Finish (EIFS or Dryvit), we also successfully completed the drywall, taping, and acoustical ceilings of the building. The skilled tradesmen of Weis along with Korte Luitjohan crafted another visually appealing, yet cost-effective and energy efficient quality restaurant.

Scott Air Force Base, IL – EIFS Project has reached an End

August 19, 2013George Weis Company was granted the opportunity to be the EIFS contractor for Potomac Leasing to perform exterior renovations on Building 1990 at Scott Air Force Base in Southern Illinois, home to the headquarters of several military organizations. A project that began mid-May of 2013 progressed throughout the summer and was completed at the end of July 2013. The exterior facade of Building 1990 had been outdated and inefficient before Weis effectively modified the existing exterior with EIFS (Dryvit). The process began with applying foam to the Hardie Plank siding that once covered the exterior of the building. In addition to the EIFS patching, the new EIFS and plaster patching, the lower skirting was replaced due to damage of the steel studs.

With their credited excellence in exterior restoration in the St. Louis area, George Weis Company successfully transformed and repaired the exterior of Building 1990 at Scott Air Force Base. The renovated EIFS building dramatically changed the appearance and increased the energy efficiency of the building.

St. Timothy’s Church Trusses Begins

May 10, 2013George Weis Company was awarded the new St. Timothy church in Creve Coeur, MO addition by the general contractor Don C. Musick Construction Company to install the steel roof trusses, load bearing steel stud walls, interior steel stud framing, drywall, taping, EIFS (Dryvit), and the acoustical ceilings (drop ceilings) on the project.

Inclement weather has delayed the project however the walls are built and trusses are being set. The end date has not changed despite the weather delays so the project schedule is fast pace.

Being one of the oldest reputable union St. Louis area plastering contractors in the area we specialize in all types of plastering whether it be EIFS on a church or brand new 120,000 SF veneer plaster schools, new stucco, EIFS (dryvit) patching, EIFS repair, stucco repair, wood lath and plaster, residential plaster repair, or any other type of plaster repair or new work.

St. Clair Catholic School Nears Completion – O’fallon, IL

March 15, 2013We are working with Holland Construction Services to install the curtain wall steel stud framing, sheathing, air barrier, insulation, EIFS, plastering contractor, acoustical ceilings, veneer plaster, and drywall on the St. Clair Catholic School in O’fallon, IL

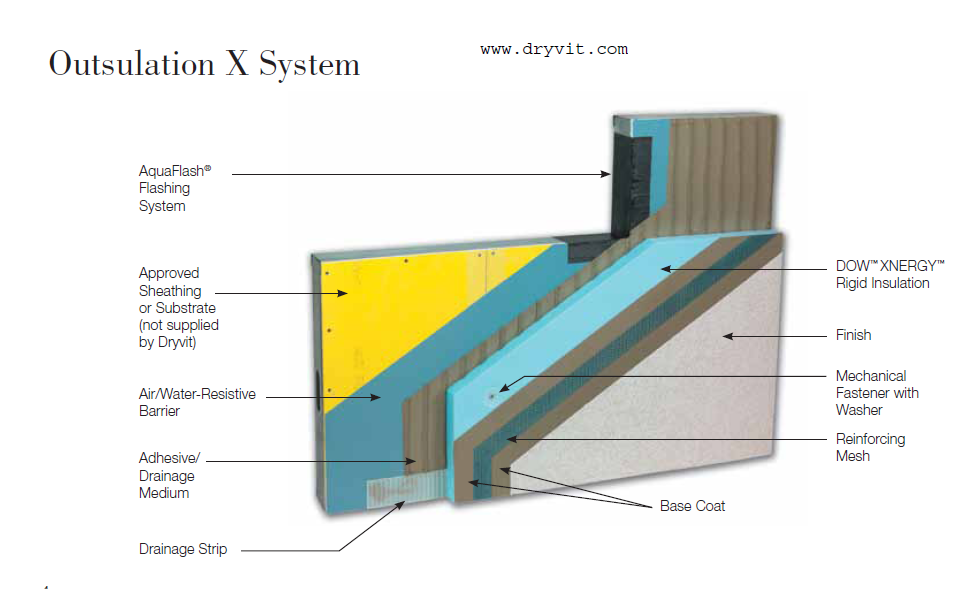

The air barrier, or drainage barrier, is the yellow fluid applied product by STO called StoGuard, bonded directly to the exterior sheathing to resist air and water penetration. With the new energy code being adopted shortly in Illinois and Missouri, fluid applied air barriers are going to be required on most buildings. We have been installing air and moisture barriers since they first came onto the market when they were primarily used behind EIFS.

St. Clair Catholic School has a unique EIFS application where we are installing EIFS over an existing metal building. This further insulates the building and retrofits it’s appearance.

Washington Avenue St. Louis Plaster Repair and Renovation

March 15, 2013George Weis Company was chosen by Lasfer & Associates to be the plastering contractor in the Historic building renovation off of Washington avenue in St. Louis, MO. The building was built at the turn of the century with most of the walls being being the old style metal lath with 5/8″ thick sand mortar plaster. Many of the existing walls were to remain with the plaster patched along with new walls to be built to match the existing plaster.

SIUE Art and Design – Plaster Progress

December 31, 2012We are working for Pottker Construction completing the interior renovation of the Southern Illinois University Edwardsville – Art and Design building. Our scope of work is the plastering contractor with Sand finish plaster, drywall, steel studs, acoustical ceilings (drop ceilings), and insulation. Phase three of four is nearly complete with the last phase finishing in the summer of 2013. The project has a very challenging schedule along with hard to reach plastering and drywall.

Having no ceiling and an exposed roof deck in a majority of the rooms, we were faced with many challenges trying to plaster around up to 50 penetrations in a single 4’x4′ wall up to 16′ off the ground. With experience union plasterers we were able to complete the difficult task with a great finished product. Above is a picture of a drywall ceiling with a radius drywall and plaster return.

Facade Renovation – Retrofit to EIFS (Dryvit)

December 28, 2012

The Heartland Bank in Sunset Hills is renovating the exterior facade of their building and changing the existing ceramic tile to EIFS (Dryvit). Hensley Construction has chosen George Weis Company to perform the EIFS, sheathing, framing, drywall and taping on the project. The existing substrate is remaining on the building and we are mechanically attaching sheathing to the existing tile and EIFS to the sheathing. The retrofit of the facade not only gives the building a whole new clean aesthetic look, it dramatically increases the thermal efficiency of the building, lowering heating and cooling costs costs by up to 30% (per Dryvit). George Weis company has successfully been retrofitting buildings with EIFS and Restoring / repairing EIFS and plaster since it began in the St. Louis area.

An interesting read on the benefits of EIFS can be found at THIS PDF and THIS PDF.